About TH Electronics

TH Electronics was founded nearly thirty years ago with a simple goal: to provide the highest quality repair services to its customers. Today, our firm is proud to be a strategic supplier of technical solutions—including equipment refurbishment, re-engineering, distribution, and supply chain and materials management—to some of the world’s leading device manufacturers.

Our dedication to high quality workmanship, rapid cycle time, and competitive pricing allows us to exceed customer expectations and build strong relationships. This focus sets us apart from other service companies and guides our decision making at every level.

LOCATION

TH Electronics operates out of a 40,000-square foot, leading-edge facility strategically located near greater Boston’s world-class medical institutions and research establishments. Our space is optimized for troubleshooting, repairing, engineering, and testing equipment used in clinical digital imaging machines. Engineering, quality, and supply chain management teams all work in close proximity to our skilled technicians.

Industry Certifications

TH Electronics’ strong customer focus, established processes, and commitment to continual improvement are reflected in the key certifications that we’ve earned.

We hold the following certifications:

Certified Six Sigma Black Belt

5S Lean Manufacturing

IPC Certifications

IPC standards help ensure superior quality, reliability and consistency in electronics manufacturing. IPC standards cover nearly every stage of the electronics development product cycle. Used by companies of all sizes in more than 90 countries across all manufacturing sectors, these standards are developed by global electronics industry experts to help the world build electronic products better.

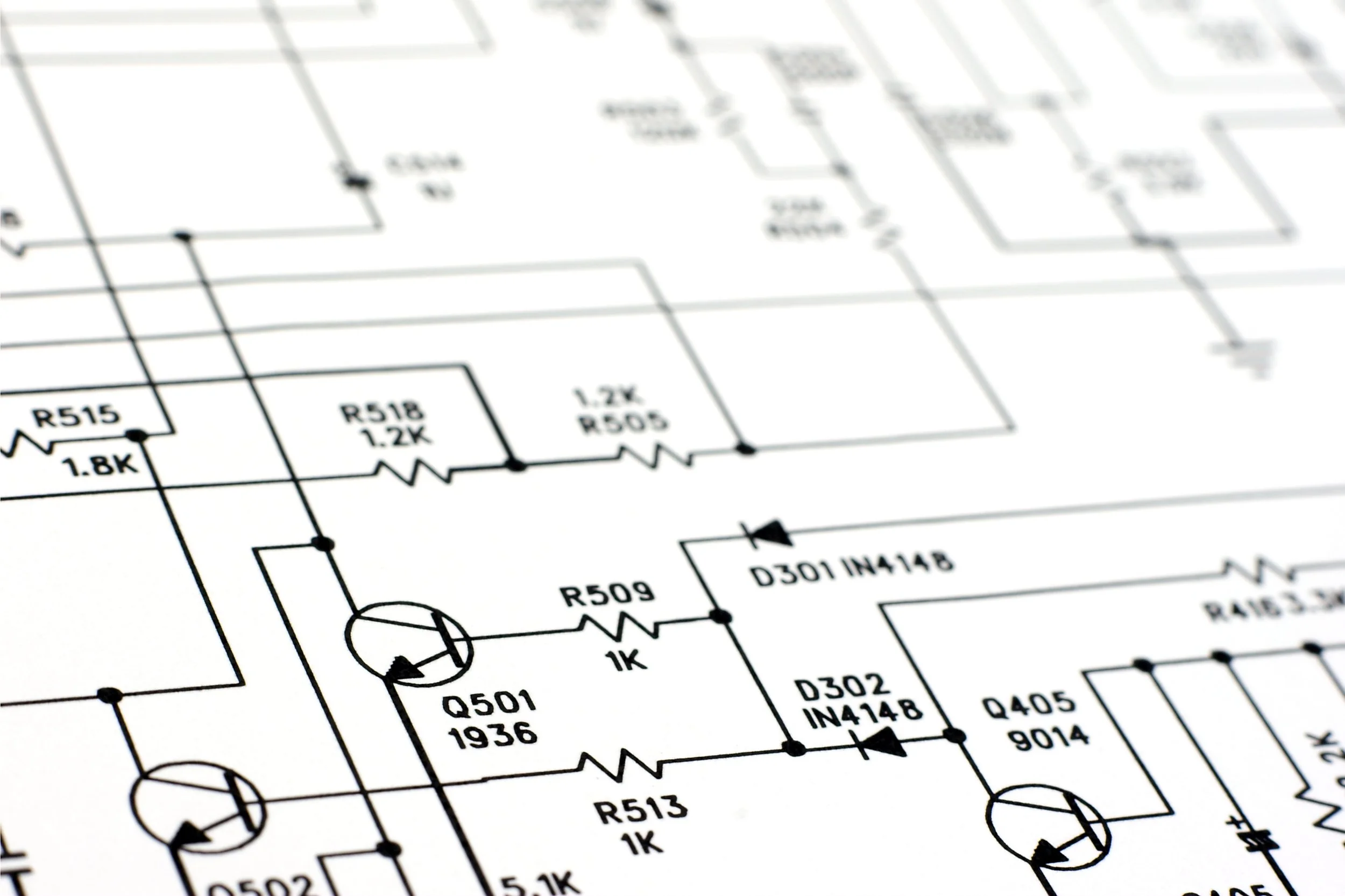

IPC A-610

The IPC-A-610 Acceptability of Electronics Assemblies Standard provides visual acceptance requirements for electronics and circuit board assembly. It is the most widely used standard published by the IPC. The standard addresses the acceptability criteria for component mounting, mechanical assembly, component attachment, solder connections, laminate condition, jumper wire installation, cable/harness lacing, and many other visually inspectable attributes of electronic assemblies.

IPC A-620

IPC/WHMA-A-620 is the industry standard for requirements and acceptance of cable and wire harness assemblies. It sets the global quality metric for manufacturing, covering materials, methods, testing, and visual criteria for a wide range of connections like crimped, soldered, and mechanically secured interconnections. The standard is essential for companies manufacturing or installing cables and harnesses and is supported by an official certification to ensure quality and compliance.

IPC J-STD-001

The IPC J-STD-001 Requirements for Soldered Electrical and Electronic Assemblies Standard, sometimes called the National Soldering Standard, is the industry’s most widely recognized standard for electronics assembly. The standard provides comprehensive criteria for the materials, methods, processes, and verification criteria for producing quality soldered connections.

IPC-7711/7721

The IPC-7711 and IPC-7721 standards were developed to provide companies with industry-accepted, step-by-step procedures for the rework, repair, and modification of printed circuit boards and electronic assemblies. They cover topics like removing and replacing components and repairing damage to circuit board layers. These standards offer clear instructions, a common language for processes, and criteria for verification, ensuring quality and consistency in the industry.